INSTALLATION

DETAIL

● Recommended Installation

| Uncoiling & Straightening | Unroll the product on the floor flat surface and straighten by hand and remove any bows. Or use a second smaller spool(or wooden drum) to straighten the product as it is taken off the larger shipping spool. |

|---|---|

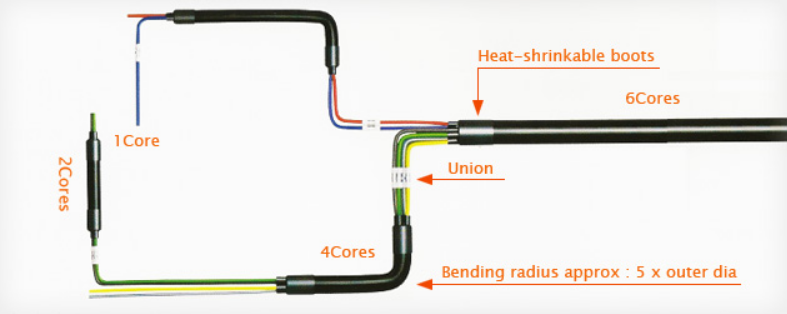

| Bending | Bend the tubing using tool or mandrel small with a radius of at least 5 times of outer diameter of the product. |

| Installation | Remove temporary end caps or seals, and install the heat shrink boots, namely cut back the filler(insulation) & sheath by sheath remover, leaving at least 30cm of tubing exposed. And slips the heat shrinkable boots over the end of the tubing and use a heat gun to shrink the boots over the tubing. |

| Support | Route the product along existing structures, such as columns and beams, to provide support. And use a support(clamp) 0.2 or 0.3cm larger than the product size. Support the product at least every 2m for horizontal runs and every 5m for vertical runs. Support must have a large surface area and be designed so it cannot be over tightened to crush the product. Do not use U-bolts & steel ties as supports if possible. |

● Schematic connection